Are you paying too much for your LTL freight shipping? In most cases, unexpected rate hikes come from inaccurate shipment details, a challenge that hits businesses of all sizes.

LTL costs are calculated based on precise shipment characteristics. But many companies struggle with accuracy, especially in freight classification and dimensions. A wrong classification can mean reclass fees, re-weigh charges, or even delivery delays. And since carriers charge by weight, size, and density, even small errors can make your freight far more expensive.

The good news: you don’t have to accept these extra costs. By avoiding common mistakes—like misstating weight, mismeasuring dimensions, or using poor packaging, you can keep expenses under control and reduceclaims. This guide will show you what’s driving up your shipping costs and how to stop it for good.

Common Mistakes That Increase LTL Costs

Misclassification is the most common and costly LTL shipping error. In fact, one in four freight bills contains a mistake that directly impacts costs. Because freight class determines your rate, even experienced shippers often get it wrong.

These mistakes usually stem from:

- Incorrect density calculations—small measurement errors can lead to the wrong freight class.

- Overlooking stowability—non-stackable freight takes more space and costs more, while stackable cargo may qualify for discounts.

- Ignoring handling requirements—fragile or hazardous goods require special care, often leading to higher classes.

Incorrect weight or dimensions also trigger expensive reclassification fees. Carriers routinely inspect pallets, and any mismatch between declared and actual freight class results in extra charges.

Another common issue is neglecting accessorial charges. Extra fees for services beyond basic transport, like liftgates or residential deliveries. These often appear only on the final invoice and can quickly eat into your LTL savings.

Finally, documentation errors on the bill of lading are costly as well. Since it’s a binding legal document, even small mistakes can cause delays, disputes, or added fees.

Packaging & Labeling Mistakes That Add Hidden Costs

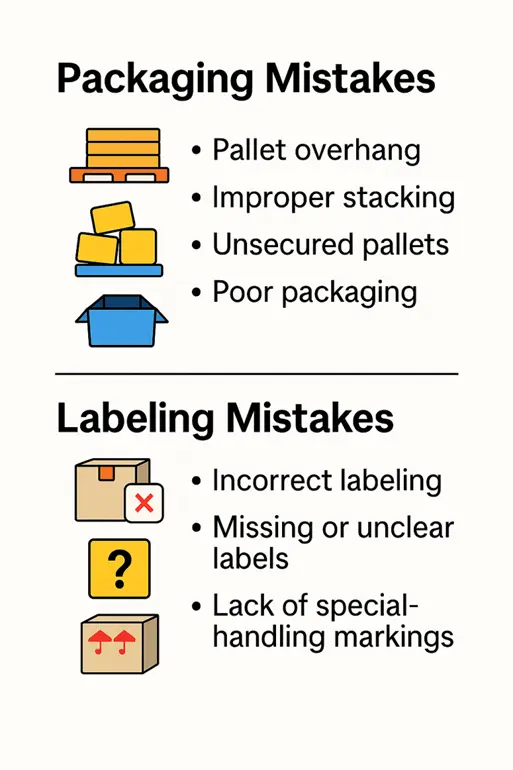

Poor packaging and labeling account for a large share of avoidable LTL costs. Mislabeled cargo causes up to 25% of shipping delays, while incorrect labels are behind roughly 30% of border crossing holds.

Pallet overhang is one of the costliest errors. It reduces box strength by up to 32%, making cartons highly vulnerable. If carriers prove poor packaging contributed to damage, they often limit liability.

Improper stacking is just as risky. Interlocking boxes can cut strength by 50%, while unsecured pallets without quality stretch wrap almost guarantee damage during the many handling points in LTL networks.

Labeling errors add to the problem. Missing or unclear labels lead to misrouted shipments, and special-handling cargo must be clearly marked to prevent mishandling.

Ultimately, carriers can deny claims if the packaging is non-compliant. That leaves you paying for the lost goods, wasted packaging, and reshipping, turning minor mistakes into major costs.

How to Avoid These Mistakes and Save on LTL Freight

Proactive steps can significantly cut your LTL costs. Start by accurately determining freight class, based on density, stowability, handling, and liability, and providing detailed shipment descriptions. Wrong classifications can cause costly re-bills and delivery delays of up to 72 hours.

Use an NMFC (National Motor Freight Classification) lookup tool to reduce disputes (by up to 30%) and always list the NMFC code clearly on your Bill of Lading. Double-check dimensions and weight before shipping to avoid adjustment fees.

Efficient packaging boosts density and reduces cubic feet. Higher density usually means a lower freight class and lower costs. Where possible, consolidate shipments to maximize density-based pricing.

Consider partnering with a 3PL provider for better carrier rates and efficiency. Businesses using Transportation Management Systems (TMS) report freight savings of 8–10%.

Lastly, safeguard valuable shipments with insurance coverage. Standard carrier liability is often just USD 20 per pound—insufficient for high-value goods. Supplemental insurance protects cargo at its actual value, not just by weight.

Conclusion

Reducing LTL freight costs starts with avoiding preventable mistakes. Misclassification, wrong dimensions, overlooked accessorial charges, and poor packaging practices like pallet overhang or unclear labels all drive up expenses and can void carrier liability. The good news is that these issues are entirely manageable: accurate freight classing, detailed shipment descriptions, proper packaging, consolidation, and support from 3PL providers can all cut costs significantly. By mastering these fundamentals, you’ll protect your bottom line and ensure you never pay more than necessary for LTL shipping.

Sources:

- https://www.easycargo3d.com/en/blog/less-than-a-truck-load/

- https://www.plslogistics.com/blog/are-you-making-these-ltl-shipping-mistakes/

- https://redarrowlogistics.com/trucking/5-common-mistakes-to-avoid-in-ltl-shipping/

- https://afs.net/blog/ltl-shipping-mistakes/

- https://www.unishippers.com/shipping-resources/freight-resources/ltl-freight-shipping-mistakes-you-could-be-making

- https://mybluegrace.com/blog/the-ltl-process-and-your-business-10-common-mistakes-and-how-to-avoid-them/

Also Read-Cremation Service in Delhi Efficient and Respectful Solutions Made Simple