Why Heavy Duty Wheels Matter

Heavy-duty wheels play a vital role in industrial settings where safety, efficiency, and reliability are paramount. In environments such as manufacturing plants, construction sites, and distribution centers, equipment must be moved smoothly and consistently—even under extreme loads and rough conditions. Because the demands placed on the wheels are so stringent, selecting robust, purpose-built wheels directly affects outcomes such as uptime and workplace safety.

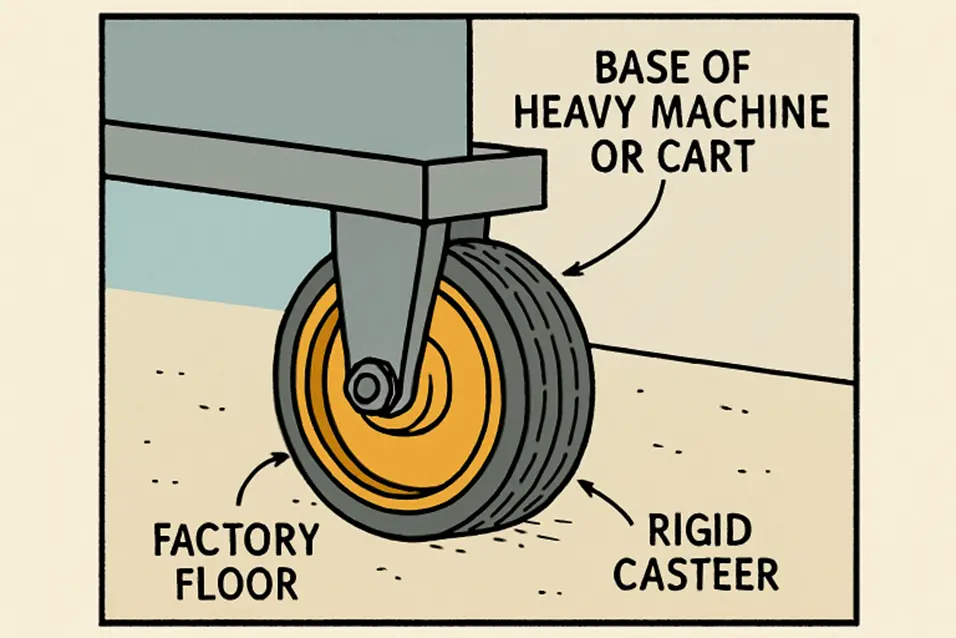

One crucial design that stands out in demanding environments is the rigid caster wheel. These wheels are specifically engineered to deliver stability and handle continuous, heavy use, where steering control is secondary to load support. Selecting the right rigid caster wheel can distinguish between seamless operation and costly equipment failures.

Key Attributes of Heavy Duty Wheels

Heavy-duty wheels are distinguished by precision bearings, wheel diameter and tread width, material composition, ergonomics, and hub design. These wheels reduce friction, facilitate easy movement, and offer stability on uneven surfaces. They also have antistatic capabilities, impact resistance, and low rolling resistance. Various industries demand wheels that support high weights safely and quietly, with advanced engineering ensuring they withstand continuous movement and stationary loading without deteriorating or presenting a risk to users.

Materials and Durability

The choice of material is central to the performance of any heavy-duty wheel. Commonly used materials include forged steel, ductile iron, and high-performance polyurethane blends. These substances are selected for their ability to withstand repeated impacts, resist flattening under extreme pressure, and hold up against corrosive agents or harsh chemicals commonly encountered in industrial settings. Polyurethane wheels often outperform rubber alternatives in abrasion resistance and operating lifespan, making them ideal for heavy-duty scenarios.

Load Capacity Considerations

Selecting the wrong wheel for the desired application can have serious consequences. Each wheel is rated for a maximum load; exceeding this limit can cause catastrophic failure. Forklifts, material handling carts, and automated guided vehicles (AGVs) routinely require wheels capable of bearing several tons, and underestimating load requirements may result in downtime, damaged goods, or even workplace injuries.

Efficiency and Safety

Heavy-duty wheels are crucial for workplace efficiency and safety. They reduce energy consumption and manual force, reducing musculoskeletal injuries. Noise-reducing treads and anti-static designs ensure a comfortable working environment. Organizations prioritize ergonomic improvements to limit workplace strain, making wheel selection with low rolling resistance even more critical. Properly chosen heavy-duty wheels are a foundation for safer, more productive operations.

Maintenance Requirements

No matter how durable, heavy-duty wheels require regular maintenance to deliver peak performance over time. Scheduled inspections should check for signs of wear, cracks, or bearing deterioration. Lubrication of moving parts can prevent early breakdown, and in high-use environments, rotating wheels between positions can reduce uneven wear. A proactive approach to maintenance not only extends the lifespan of costly components but also helps prevent hazardous, unscheduled equipment failures that cause downtime.

Final Insights

Choosing the right heavy-duty wheels is essential for safety, efficiency, and longevity in demanding industrial environments. By focusing on material quality, load capacity, and proper maintenance, organizations can ensure smooth operation, reduce