By 2025, the packaging industry has changed dramatically due to shifts in consumer needs, compliance, and the digitalization of supply chains. Within these shifts, can labeling machines have surfaced as critical investments to improve traceability and enforce brand identity especially for high-volume compliance-driven businesses in food, beverages, pharmaceuticals, and chemicals.

For B2B businesses aiming for greater packaging efficiency and accuracy, the adoption of automatic packaging solutions in production lines is no longer optional. It has become a strategic imperative. Labeling systems, especially used for cans and cylindrical form packaging, have greater expectations than just placing labels. They must also ensure legible, accurate, aligned labeling and real-time information integration.

Let us examine the effects of can labeling technology on the packaging value chain, as well as the speed, compliance, and brand consistency automation enables manufacturers to deliver.

The Role of Labeling in Supply Chain Digitization

As supply chains become more intertwined within the industry, labeling has grown in importance for tracking shipments. Labels are now dormant as carriers of important information such as batch numbers, expiration dates, and even the recycling information label. In the case of can-packaged goods, the label serves as the primary channel of information exchange between the manufacturer and the end user.

Traceability is important in the B2B distribution networks. It does not matter if it is a soft drink company who needs to appropriately keep track of space and lots, or a pharmaceutical company that needs to track and comply with serial number requirements. Can labeling machines make it possible for products to be tracked and traced, and accounted for, everywhere and at any time.

State of the art automatic packaging solutions equipped vision systems, labeling machines, barcoding modules, and even cloud based tracking software to form a closed loop systems which simultaneously:

- Increases compliance in global markets whereby regulations are followed

- Makes recall of products more efficient

- Prevents counterfeiting and grey-market diversion.

- Greater responsibility in multi-tier supply chains.

The cosmetic labeling process of the packaging line has now been transformed into a critical control point for the line.

In What Ways Labeling Machines Are Improving Brand Recognition

Maintaining brand identity goes far beyond a logo, as it encompasses focus, consistency, precision, and clarity. In a crowded marketplace, B2B trades where packaging is meticulously scrutinized, reputations are built on trust and diligence, thus, brand mislabeling, tarnishes reputations.

Can labeling machines of 2025 are futuristic and equipped with high-resolution applicators and servo-controlled motors with millimeter precision. The seamless brand consistency and accuracy during labeling enhances brand image. Professional brand packaging reinforces identity, and is crucial for:

- Craft beverage producers appealing to retail outlets.

- Paint and chemical industries require waterproof and durable labels.

- Food exporters and multilingual label compliance.

- Premium nutraceutical brands SKUs positioning.

Today’s dynamic packaging demands are met with advanced labelers which enable agile design alterations to support limited-edition prints, seasonal promotions, or distributor-specific branded packaging.

Summary encapsulation: 2025 Can labeling machines and automatic packaging solutions will allow brands and manufacturers to effectively and effortlessly meet dynamic agile demands, enable packaging at scale, while maintaining visual accuracy.

The Latest Features in Can Labeling Machines

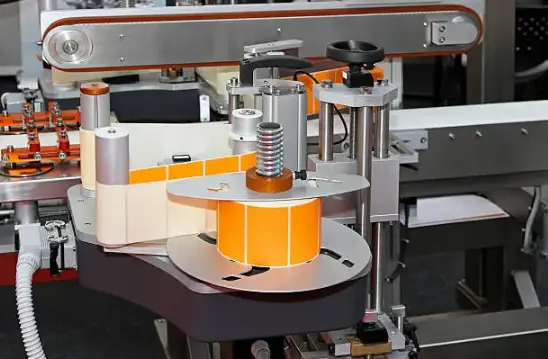

The latest generation of can labeling machines goes beyond simple label application with advanced label application accuracy to meet compliance and high-speed production requirements.

Smart Vision Inspection Systems

Contemporary labels feature integrated vision systems that check every label for placement, wrinkles, skew, and printing. This kind of inspection streamlines the removal of defective items in real-time, greatly reducing expensive recalls.

Modular and Scalable Design

Labeling systems today come with modular architecture, greatly easing scalability for manufacturers. There are modular label applicators, integrated camera systems, and print-and-apply units that can be incorporated as needed.

Dynamic Labeling for Serialized and Variable Data

Labels can now bear dynamic information printed during their application by thermal transfer or inkjet modules. This is crucial for pharmaceutical serialization as well as for marketing and traceability. Nutritional value information and promotional codes are also of importance.

Easy Integration with MES and ERP Systems

Labeling machines now feature MES and ERP compatible data communication interfaces. This allows automated data transfer and real-time monitoring of production, streamlining the processes.

These improvements and others boost the value of labeling machines within comprehensive automatic packaging solutions, transforming them from simple packaging devices into sophisticated digital data systems within the Industry 4.0 framework.

Enhancing Business Productivity through Automation

Correct and precise labeling impacts packaging line productivity and compliance while manual labeling has a number of inefficiencies. In today’s modern high-paced factories, let alone balance speed, accuracy, and compliance, a sluggish system with no traceability is a huge liability.

Automatic can labelers provide the following operational advantages:

- Achieve accuracy and precision. repetitive tasks become monotonous, human operators make errors but servo motors ensure precision repeatability with high accuracy.

- Reduction in processing and idle time. Advanced automation systems enable real time adjustments and misalignment can be corrected on the go while separate label and cap systems can operate in tandem.

- Vertical growth with the need of minimum investment. Advanced systems with intelligent scalable designs need minimum human supervision, supporting gear is less.

The accuracy and repeatability offered with servo systems helps maintain competitive operational margins and aligns with the streamlined approach of lean manufacturing. They also aid automatic packaging systems which include conveyors, fillers, cappers, and palletizers.

Meeting Compliance and Sustainability Objectives

With sustainability measures getting stricter on a global scale, labeling machines are being enhanced to meet eco-friendly and regulatory compliant packing standards. Here is how:

- Eco-Friendly Materials: Utilization of biodegradable, recyclable, or linerless labels is supported.

- Energy Efficiency: Adoption of newer models fully offers power-saving and regenerative braking features.

- Reduced Waste: Label rejection and misfeed through intelligent control systems is minimized.

- Multi-standard Compliance: A centralized system can issue region-specific labels including US and EU nutrition info.

Traceability through labeling also supports ESG initiatives by monitoring carbon emissions, the origin of production, and the recyclability of materials. This is vital for business to business B2B purchasers.

To secure a competitive edge in the market, enhanced compliance and sustainability meets eco-friendly standards for long-term market positioning.

Conclusion: Modern B2B Manufacturers: Strategic Investment

Labeling is a critical core business function with swift consumer-response feedback, multi-nation regulatory frameworks, and intricate supply chains. Can manufacturers value the accuracy, visual transparency, and traceability modern labeling machines offer?

Integrating these labelers within broader automatic packaging solutions allows businesses to:

- Improve production optimization

- Decrease workforce errors and associated costs

- Maintain comprehensive global market traceability

- Improve corporate identity and consistency across product packaging

- Maintain market and regulatory responsiveness

As such businesses no longer view packaging as solely a concluding step—the automation and strategic preparation of labels play a crucial role in structural packaging. Innovative label automation in business to business systems will further streamline operations to propel productivity in anticipation of the evolving marketplace of 2025 and beyond.

Also Read- How Audio Branding Can Enhance Your Business